Case Study

The Challenge:

A large automotive dunnage manufacturer asked us to make large plastic inserts from a single sheet of HDPE.

The APS Solution:

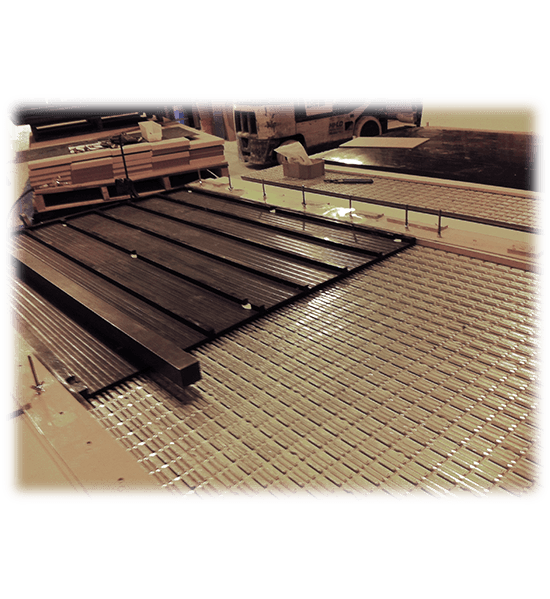

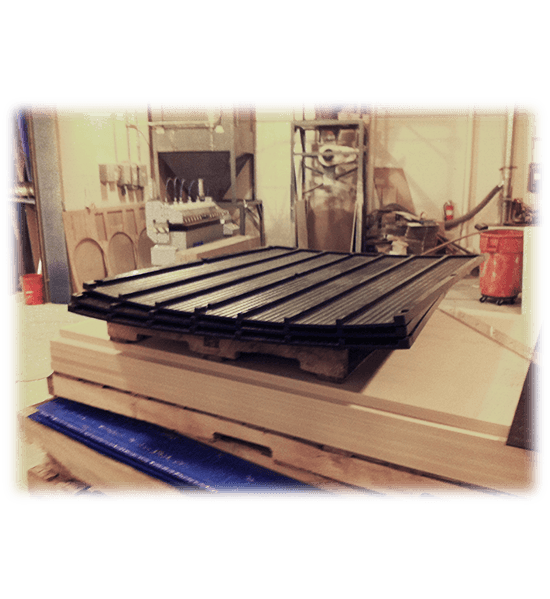

We gave the customer the geometry and material they needed for part holding, but instead of cutting the entire unit from a single sheet of 1- 1/4 inch thick HDPE, we redesigned the part with a single body with multiple rails assembled to it.

The Result:

This approach saved hundreds of machine hours and thousands of dollars worth of material. In the end, the customer saved over $30,000 on a $100,000 project, and tons less waste went into the landfill.