Case Study

The Challenge:

Our customer wanted to eliminate the expensive and hazardous transportation and storage of volatile liquid chemical compounds used for hemodialysis with their kidney patients.

The APS Solution:

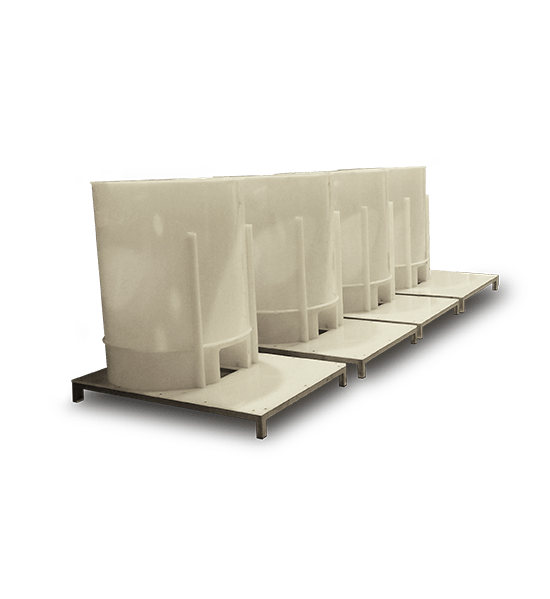

We worked with our customer/partner to develop a system for making liquid chemical compounds on-site at kidney dialysis centers with dry acid compound and distilled water. Our tank is supplied complete with plumbing holes, threaded couplings, stainless steel threaded inserts for assembly, a stainless steel floor platform and all the packaging required for final assembly and shipment to the customers’ north American sites.

The Result:

Greatly reduced customer assembly labor from our supplied tank to the finished tank assembly with pump, sensors, electronic controls and packaging included. The on-site mixing gives better quality, lower cost, reduced transportation, and no storage issues. The hemodialysis compound has longer usable life after mixing on-site. This saves time, money and lives. A true happy ending for all of us.