Case Study

The Challenge:

A major international automotive parts supplier needed to tumble plate and clean parts continuously at their Midwest factory.

The APS Solution:

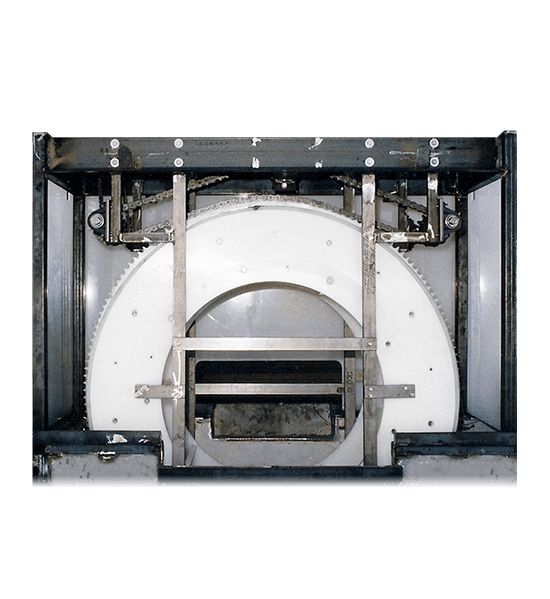

We built a beautiful chain-driven polypropylene barrel 4 feet in diameter and 18 inches deep. The body is a 1-inch thick shell with through holds that is thermoform and butt welded into a 4-foot diameter tube. The front and back annuli are N/C machined and fit into the body like a glove. We added interior paddles to move the parts as the whole barrel rotates on linear bearings. The barrel rotation is driven by custom-machined polypropylene sprockets which are made with a stainless steel drive unit. The sprockets and paddles are modular so they can be easily replaced after many years.

The Result:

Years and years of 24/7 operation without a glitch. Set it and forget it!